Water proof

Eco-friendly

UV-resist

Low maintenance

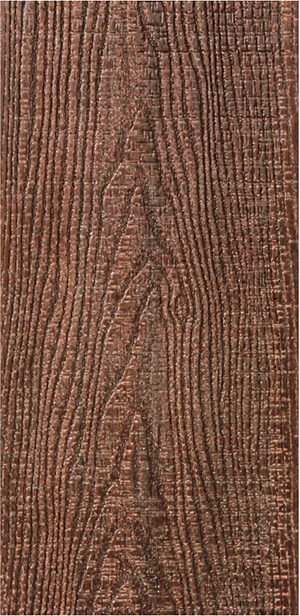

Wood Vein

Matt Texture

Saw Mark

Smooth Surface

Stripe

Ripple

Flamelet

Starfield

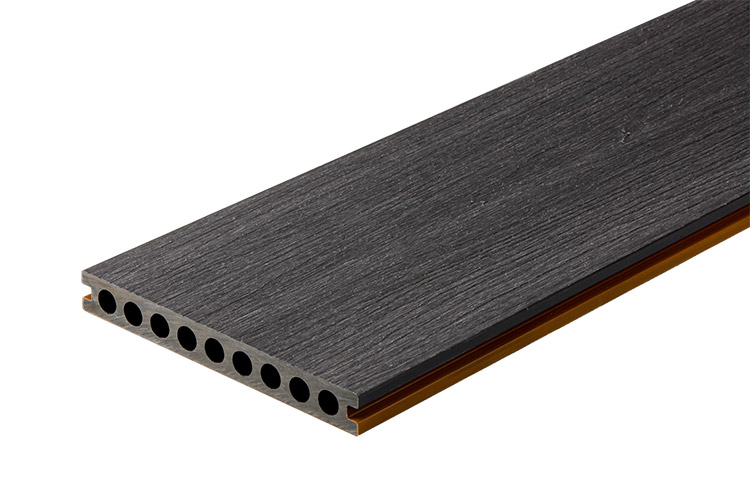

√ Co-extruded decking

√ Reversible and removable profile

√ Different surface finish

√ Wood relief grained surface

√ Multi-chromatic colours

√ Stain and fading resistant

Co-extruded protection layer

Reversible profile: 2 effective sides

40% Polyethylene HD + 60% Wood fibre

23 x 190 mm

GWA014 stainless steel clip

Co-extrusion 360°

Pendulum value≥36

Mean ≥ 3300 N Min. ≥ 3000 N

Mean≤7% Max<9%

Class B

Grinwood WPC Material Co., Ltd. warrants to the original purchaser (“Purchaser”) that, for the period of times set forth in the following sentence, under normal use and service conditions, Grinwood product shall be free from material defects in workmanship and materials, and shall not split, splinter, rot or suffer structural damage from termites. The term of such warranty shall be fifteen (15) years from the date of original purchase for a residential application, and ten (10) years from the date of original purchase for a commercial application.

Grinwood guarantees the resistance of Co-extrusion deck boards to stains and fading, subject to compliance with instructions for installation and use in residential applications.

Grinwood Co-extrusion decking is fully resistant to stains, and its radiance is sustained by a co-extrusion process, which covers the board with a pure polyethylene film to ensure perfect sealing of the coating. Maintenance is easier and is limited to simply rinsing with water.

Grinwood Co-extrusion Decking is an environmentally-friendly product. 90% manufactured with raw materials from the recycling industry, decking boards are also entirely recyclable.

High-density polyethylene (HDPE) comes from the recycling of plastic waste (plastic bottles), and the wood fibers come from sawdust from manufacturers such as furniture makers.

Manufacturing Grinwood decking boards does not harm tropical forests and is an attractive alternative to exotic woods.